Toxicological and eco-toxicological impact assessment of disinfectants (Product benchmarking)

Toxicological and eco-toxicological impact assessment of disinfectants (Product benchmarking)

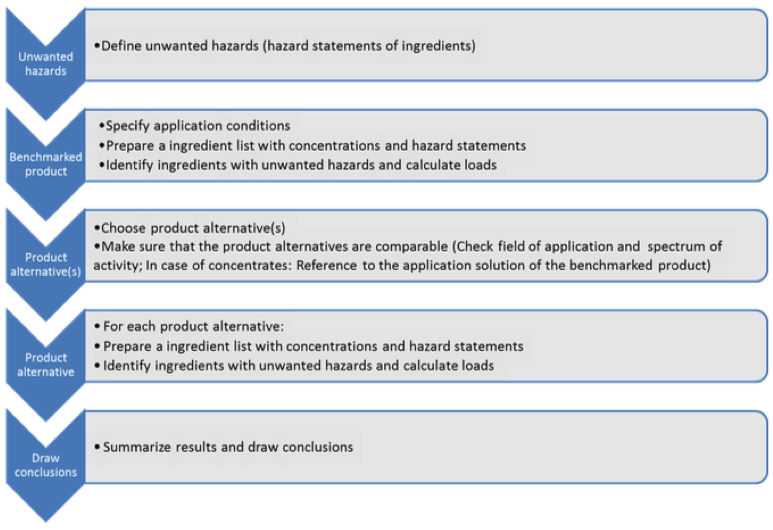

Product benchmarking is the comparison of attributes of a product or product portfolio with a “benchmark”. As a general rule the benchmark is the market leader in a particular product segment. The comparison can be used to derive potential for the own product. In the impact assessment at hand toxicological and eco-toxicological properties of disinfectants are subject to a benchmarking. These properties pose a potential threat to human health and the (aquatic) environment. Responsible for these properties respectively threats are the ingredients. The impact assessment applies the hazard statements (H-statements) of the ingredients laid down in their classification. The assessment starts in specifying which hazard statements are of particular concern and therefore should be avoided. For product benchmarking a adequate market overview is needed. This is provided by the WIDES database[1]. The WIDES includes more than 240 disinfectants available on the market for the following fields of application: Surface disinfection, hand and skin disinfection, instrument and linen disinfection. If benchmarking of a product is planned, appropriate “benchmarks” can be investigated in the WIDES. The product benchmarking foresees the following procedure both for the product to be assessed and the product alternatives (benchmarks):

FIGURE 1: PRODUCT BENCHMARKING OF DISINFECTANTS

[1] https://de.wikipedia.org/wiki/Produktbenchmarking

Case study

The following case study is an excerpt of the consultation project Assessment of disinfectants applied by the City of Vienna from a toxicological perspective in the years 2014-15. The assessed disinfectant P3 is one of several disinfectants used for routine surface disinfection in public baths

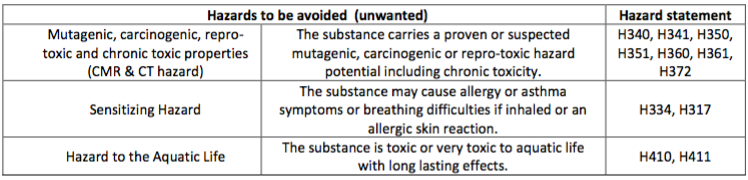

Define unwanted hazards

Based on the analysis of the Biocidal Products Regulation[2], REACH[3] and the Austrian ArbeitnehmerInnenschutzgesetz[4] the following hazards were defined as to be avoided and therefore as unwanted[5] :

Specify application conditions

The annual use amount of P3 is 1005 litres concentrate. According to the WIDES database P3 is certified for surface wipe disinfection. The relevant spectrum of activity is: bactericidal (not Mycobacteria) + yeasticidal with clean conditions plus mechanical action. To reach the certified efficacy a 0.5 % dilution of P3 has to be distributed on the floor and left to act at least for one hour.

[2] https://echa.europa.eu/regulations/biocidal-products-regulation

[3] https://echa.europa.eu/regulations/reach

[4] https://www.arbeitsinspektion.gv.at

[5] See also the explanatory chapter: IDENTIFYING CRITICAL SUBSTANCE PROPERTIES:

Ingredient list with concentrations and hazard statements

The next step was to list the ingredients with their concentrations. This information was excerpted from the WIDES database (“Product components”) and transferred into an excel sheet. Only product ingredients which are both classified and have concentration details were considered. If a concentration range was given the higher value was taken. The WIDES provides the ingredient’s classification in two forms:

- H-phrase according to safety data sheet: In this column the hazard statements given by the manufacturer in his product safety data sheet are cited.

- H-phrase according to WIDES: In this column a consolidated version of the hazard statements used for the WIDES assessment is given.

Since the latter is compared with the classification given in REACH Dossiers or Risk Assessment Reports it is more reliable and relevant. Therefore this classification is taken over into the list.

Identification of ingredients with unwanted hazards and calculation of loads

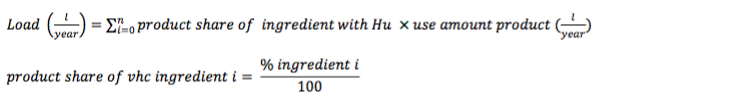

For each ingredient with an unwanted H-Statement (Hu) the load is calculated as follows:

For P3 the used amount of product is 1005 litres concentrate. In Table 1 hazard statements identified as unwanted are indicated in column 4. Columns 5, 6 and 7 indicated the calculated loads. Finally a conversion is made from litre into kilogram. The density of P3 according to the Safety Data Sheet is 1.03 which in the example is roughly estimated with 1 kg/l. If however the density deviates significantly from 1 (e.g. for alcohols) the real density has to be considered. The result can be summarized as follows: The use of product P3 generates an annual load of 75 kg substances with unwanted hazard. The calculated load affects to 100% the aquatic life.

For P3 the used amount of product is 1005 litres concentrate. In Table 1 hazard statements identified as unwanted are indicated in column 4. Columns 5, 6 and 7 indicated the calculated loads. Finally a conversion is made from litre into kilogram. The density of P3 according to the Safety Data Sheet is 1.03 which in the example is roughly estimated with 1 kg/l. If however the density deviates significantly from 1 (e.g. for alcohols) the real density has to be considered. The result can be summarized as follows: The use of product P3 generates an annual load of 75 kg substances with unwanted hazard. The calculated load affects to 100% the aquatic life.

TABLE 1: ANNUAL LOAD OF SUBSTACNES WITH UNWANTED HAZARD

Choosing product alternative(s)

The applicator is free to choose any product(s) for comparison purposes as far as the product alternatives have the same application and provide at least equal bactericidal, yeasticidal, fungicidal, virucidal or sporicidal efficacy. The product alternatives for the case study were not freely chosen but queried in the WIDES database[6]. For that the following procedure was applied:

- After Log-In and opening the modul Products the application Surface Wipe Disinfection was activated.

- In the drop-down list the exposure time 1h and the spectrum of activity bactericidal (not Mycobacteria) + yeasticidal, clean cond. + mechanic action was selected and afterwards the button Go to assessment was pressed.

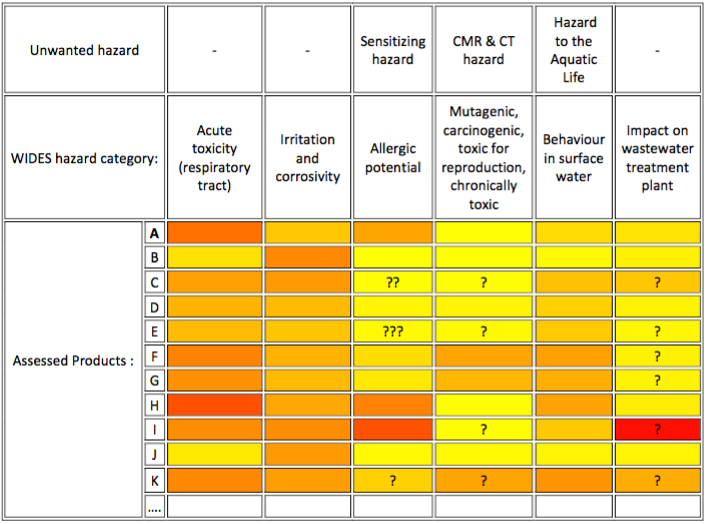

The query resulted in a list of product alternatives for P3 (product name, manufacturer, active ingredients) together with their WIDES assessment in six hazard categories[7]. In the case at hand the WIDES query delivered 31 product entries. From these in a next step three products were selected as “Best Case” (comparatively low hazard potential) and three products as “Worst Case” (comparatively high hazard potential). The selection was made by means of the WIDES product assessment. The assessment is presented visually in terms of colour fields from pale yellow (low hazard), orange (medium hazard) to deep orange or red (high or very high hazard). Question marks in the colour fields indicate data gaps in the underlying dataset. External users are dependent on a visual analysis respectively interpretation of the spectrum of colours[8].

Choosing product alternatives according to figure 2 (visual analysis):

- Benchmarks with a comparatively low hazard potential (Best Case) would be products B and J (Colour fields in the hazard categories Allergenic potential; Mutagenic, carcinogenic, toxic for reproduction, chronically toxic and Behaviour in surface waters are pale yellow).

- Benchmarks with a comparatively high hazard potential (Worst Case) would be products F and K (Colour fields in the hazard categories Allergenic potential; Mutagenic, carcinogenic, toxic for reproduction, chronically toxic and Behaviour in surface waters are deep yellow or orange)

FIGURE 2: LIST OF PRODUCTS FOR BENCHMARK

[6] https://www.wien.gv.at/english/environment/protection/oekokauf/disinfectants/index.html

[7] A seventh hazard category (flammability) is foreseen for disinfectants which are flammable, but this is not relevant in the case study at hand. A detailed explanation of the product assessment and the algorithm can be found in training videos and the pdf Introduction to the assessment framework on the WIDES webpage

[8] The system administrators of the WIDES can additionally reference to the product assessment numbers which are invisible for the external users.

Securing, that product alternatives are comparable

By using the WIDES database for choosing product alternatives it is automatically ensured that P3 and their alternatives are comparable in the field of application and the spectrum of activity. The product P3 is – since it is listed in the WIDES – part of the product list. If the WIDES is not used for the choice of product alternatives, the comparability has to be ensured by means of the specifications of the manufacturer and certificates[9]. In case that concentrates are compared, the following has to be considered: Since both the benchmarked product P3 and the product alternatives have to be diluted prior to application the calculation of the load has to be referenced to the amount of application solution of the benchmarked product. Since for P3 the concentration for application is 0.5% and the annual consumption is 1005 litres concentrate this results into an annual application solution of 201.000 litres. Therefore the product alternatives also have to generate 201.000 litres of application solution. This can lead to different amounts of concentrates: If a product alternative is used as a 1% application solution, then 2010 litres of concentrate is needed to generate 201.000 litres of application solution.

For each product alternative: Prepare an ingredient list with concentrations and hazard statements; identify ingredients with unwanted hazards and calculate loads

In the case study at hand 6 product alternatives were selected namely 3 as Best Case benchmarks and three representing Worst Case benchmarks. For each product alternative an ingredient list has been established and loads were calculated.

[9] For example as an entry in the disinfectant list of the German VAH (http://www.vah-online.de/) or the Austrian ÖGHMP (http://oeghmp.at/)

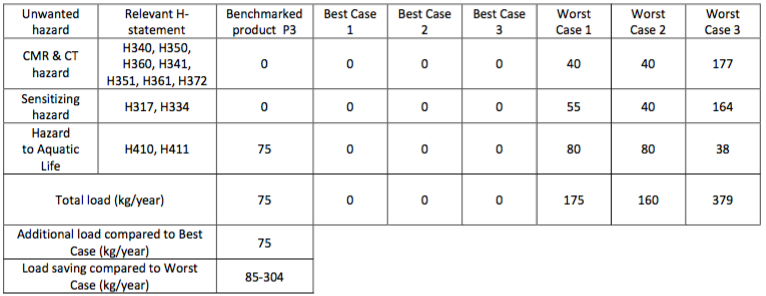

Summarize results and draw conclusions

Since the benchmarking in its essence is a comparison the summary and presentation of the results are a crucial point of the method. For that options for presentation in terms of tables, graphs and text are presented below. They are an excerpt of the consultation project. Therein the product P3 is compared with the three “Best Case” and the 3 “Worst Case” alternatives.

TABLE 2: PRESENTATION OF OUTCOME BENCHMARKING P3

FIGURE 3: PRESENTATION OF OUTCOME BENCHMARKING P3

FIGURE 3: PRESENTATION OF OUTCOME BENCHMARKING P3

| Overall conclusion / recommendation:

The use of product P3 generates a load of 75 kg substances with unwanted hazards. The load affects the aquatic environment up to 100 %. There are products available on the market for the same application and with the same efficacy which emit 0 kg of substances with unwanted hazard. With the limitation that material incompatibilities and working conditions are not explicitly taken into account a substitution of P3 should be taken into consideration (potential for improvement). |